Empire Metals Restricted, the AIM-quoted and OTCQB-traded exploration and improvement firm, is happy to report important progress in metallurgical testwork at its Pitfield Challenge in Western Australia (‘Pitfield’ or the ‘Challenge’). These outcomes affirm that the weathered ore at Pitfield may be processed utilizing typical separation and refining strategies, delivering industry-leading recoveries and a high-purity titanium dioxide (TiO₂) product.

Highlights

Distinctive flotation efficiency: Recoveries of 77% (rougher stage) and 90% (cleansing stage) from fantastic, weathered ore samples.Excellent leach outcomes: Direct acid bake and hot-water leach achieved 98% titanium dissolution, leaving inert quartz residues.Excessive recoveries: General titanium restoration from flotation feed to closing product is circa 67% and anticipated to enhance with additional optimisation of the mineral separation phases.Excessive-purity closing product: TiO₂ grading 99.25% with negligible impurities, appropriate for titanium sponge steel or pigment manufacturing.Price and environmental benefits: Low Fe₂O₃ (~5%) reduces acid consumption, minimises waste, and helps greater recoveries over typical ilmenite feedstock processing.Simplified, expedited improvement pathway: Amenability to plain mineral separation eliminates the necessity for a expensive bespoke demonstration plant, enabling a lower-cost steady pilot programme utilizing accredited business laboratories.

Shaun Bunn, Managing Director, mentioned:

“These outcomes mark a step change in Pitfield’s improvement. We now have clear proof that the ore is ideally suited to traditional mineral separation and refining, producing a high-purity titanium product with sturdy recoveries. This units Pitfield aside from ilmenite-based initiatives, which generally face decrease recoveries, greater prices, and important environmental challenges.

“Pitfield already stands out for its distinctive scale, continuity of high-grade near-surface mineralisation, and Tier 1 location with entry to infrastructure. With this breakthrough in course of improvement, we are able to now show a extremely environment friendly and environmentally accountable path to producing a number of high-value titanium merchandise.”

Metallurgical Testwork Abstract

Empire has dedicated substantial monetary assets to creating a metallurgical flowsheet that may economically extract titanium and produce a excessive worth titanium product: akin to TiO2 pigments, and/or feedstock for the TiO2 pigment or titanium sponge metals industries.

The method to flowsheet improvement has included:

Intensive mineralogical investigations on exploration samples, testwork feed samples and testwork productsWide ranging literature opinions, together with {industry} and cross-industry researchIdea technology and testing of ideas and situations within the laboratoryA fast-tracked separate work programme to show that an impurity free excessive grade product may be created from samples taken at Pitfield.

Preliminary mineralogical and metallurgical testwork was undertaken on the recent, titanite-rich bedrock mineralisation at Pitfield and returned encouraging outcomes. Following the identification of the in depth in-situ weathered cap, which independently represents a generational-scale mining alternative, subsequent testwork programmes have been directed towards this materials. The weathered cap incorporates primarily anatase and rutile, and is distinguished by its smooth, friable texture, elevated titanium grades, and near-surface publicity which supply important benefits from each a mining and processing perspective.

Empire has employed two full time course of engineers to work on the method flowsheet improvement, each of whom have in depth expertise in mineral separation and elemental extraction (hydrometallurgy). As well as, Empire has contracted with two titanium professional consultants, every of which has over 40 years’ expertise within the {industry}. The method improvement programme can be supported by additional specialist enter from the technical group at Strategic Metallurgy, scientists from Federal Authorities companies and course of engineers from native Engineering & Course of Design Consultants.

Testwork outcomes achieved up to now are encouraging and assist the conceptual course of flowsheet that was introduced 4 September 2024 “Constructive Outcomes Achieved from Preliminary Processing Testwork on Pitfield Titanium Ore” (refer Determine 1).

Determine 1. Conceptual Course of Flowsheet.

Latest testwork has been targeted on the fantastic, saprolite ores from the Thomas prospect. Testwork outcomes up to now counsel that Empire can anticipate to realize an total restoration of circa 65-75%, and produce a high-purity, +99% TiO2 product. That is based mostly on early stage testwork with restricted optimisation, and the success up to now is an efficient indicator that the Pitfield ores are non-refractory and freed from deleterious contaminants that have an effect on product high quality (akin to U, Th, Cr, P and V).

While it’s troublesome to supply comparable initiatives to Pitfield, given its scale, grade and distinctive ore traits, the processing route being evaluated for Pitfield has related phases to that discovered within the well-established heavy mineral sands {industry}. For example, the ilmenite inside the mineral sands is first separated (by gravity and magnetics) and the ilmenite concentrates are then beneficiated by a mix of discount roast and leach to supply artificial rutile. This in flip turns into feedstock to the TiO2 pigment or Ti sponge steel producers, each of which use sturdy oxidants (Cl fuel or sulphuric acid) and excessive temperatures to rework the feedstock into pigments or TiCl4.

The entire technique of recovering titanium from ilmenite; concentrating, beneficiation after which remodeling it right into a high-purity product is inefficient (usually low recoveries), costly (excessive power consumption and costly consumables) and environmentally unfriendly (substantial Fe residues to get rid of from the breakdown of the ilmenite). The distinctive ore traits of Pitfield present a possibility to design a brand new processing route that’s extra environment friendly, decrease value and has higher optionality over the merchandise it might probably produce than that at present skilled by the ilmenite processors, who account for 95% of the titanium provide chain.

Metallurgical Samples

Samples getting used for the testwork programme have been collected from drilling programmes performed throughout the deposit. These embody drill core samples from diamond drilling, and bulk samples from air core drilling programmes. Samples have been collected from each exploration targets – Cosgrove (‘COS’) and Thomas (‘TOM’). Separate Saprolite (‘SAP’) and Weathered Sandstone (‘WS’) zones have been recognized. Among the testwork samples are a mix of the 2 zones and a few have been stored separate to grasp the efficiency of the weathering profile.

Mineralogy

Various mineralogy strategies are getting used to develop the understanding of the Pitfield mineralogy and morphology. SEM based mostly TIMA evaluation has been undertaken at Automated Mineralogy Incubator (AMI) on exploration samples, testwork feed samples and testwork merchandise.

Determine 2. Mineralogist at AMI discussing Pitfield TIMA evaluation outcomes with Empire Metallurgist

Key data collected from TIMA evaluation on testwork feed samples and exploration samples contains the titanium and gangue minerals current, the grain sizes, and the mineral affiliation.

Testwork product samples have additionally been analysed utilizing TIMA to grasp the deportment of the completely different titanium minerals and effectiveness of every of the processing steps. Greater than 100 samples have been analysed utilizing TIMA, together with geology samples, testwork feed samples and testwork merchandise.

XRD evaluation has additionally been used on a spread of samples. This has been used to assist with mineral identification that SEM can’t decide – such because the crystal construction of titanium oxide minerals, figuring out them as both anatase or rutile.

Microprobe evaluation, at CSIRO in Melbourne, has been used on a small variety of samples: to measure impurities in titanium minerals specifically.

Testwork – Flowsheet Growth

Some early testwork programmes have been undertaken utilizing recent mineralisation from Pitfield, nevertheless as soon as an understanding of the mineralogy and quantity of the weathered zone was developed, the main focus shifted to this materials.

Comminution and Mineral Separation

A number of comminution checks have been accomplished on drillcore samples to research potential for low power enter comminution akin to scrubbers and log washers. The optimum regrind liberation dimension vary and the power enter required, which seems to be very low, continues to be investigated.

A variety of unit processes are being investigated for mineral separation utilising whole-of-ore samples in addition to separated coarse and fantastic fraction samples.

Testwork on the coarse fraction has targeted on gravity and enhanced gravity separation, testing shaking tables, spirals, and a Multi Gravity Separator (MGS). The shaking desk checks and MGS checks have been accomplished at batch scale (~5-20kg), while the spiral checks have been undertaken on a a lot bigger, bulk scale (~300-600kg).

Testwork on the fantastic fraction checked out enhanced gravity (MGS) and froth flotation. A spread of flotation reagents and situations are being examined. Related examples exist within the non-sulphide flotation {industry}, together with anatase flotation from kaolin clay minerals within the kaolinite {industry}.

Entire-of-ore testwork is within the planning phases for comparability in opposition to gravity separation efficiency. This testwork will concentrate on grinding, flotation after which additional remedy of the flotation focus assessing various completely different separation processes.

Key outcomes up to now embody:

· High quality fraction “rougher” flotation on a TOM SAP pattern has achieved 67- 77% TiO2 restoration and as much as 19% TiO2 focus grade. Related restoration efficiency was achieved on a COS WS pattern fines fraction with a “rougher” flotation restoration of 68%.

· Cleaner checks on rougher focus from the TOM SAP rougher flotation check achieved a 90% stage restoration at 32percentTiO2 focus grade. This equates to an total float restoration of circa 70%.

· Bulk scrubber testwork on TOM SAP pattern resulted in 51% of the mass and 72% of the contained TiO2 to the fines fraction, utilizing a hydro cyclone. Related outcomes have been seen on a smaller scale scrubber check utilizing drillcore materials, with 53% of the mass and 66% of the TiO2 reporting to the fines fraction, utilizing a 38µm display screen.

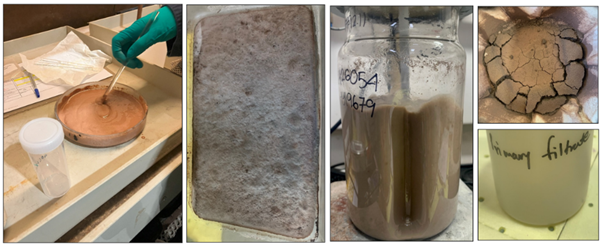

Figure3. (L-R): Bulk Scrubber check in progress at AML, Batch slimes fraction rougher flotation check at ALS.

Elemental Extraction and Product Ending

A variety of ideas are being explored for extraction of titanium from the mineral focus. These vary from typical processes, already utilized within the titanium {industry} or different comparable industries, to extra novel processes which have been developed by laboratory analysis and pilot scale testing.

A base case of sulphuric acid bake water leach, adopted by titanium hydrolysis and calcination has been examined by Empire. That is based mostly on the standard sulphate route for TiO2 pigment manufacturing, which is normally utilized to ilmenite concentrates. A spread of different lixiviants and decomposition and leach situations have been recognized and are deliberate to be examined as a part of the continued improvement programme.

Product ending testwork goals to take titanium from the leach options and produce a closing product. It’s intently tied to the basic extraction, so in some instances is being examined as a part of that testwork programme. There’s a vary of product choices: separate analysis testwork is being undertaken to develop and understanding of the assorted TiO2 pigments and Ti chemical compounds that Pitfield can produce and the markets through which these merchandise are required.

Round 15 leach checks have been accomplished up to now, together with 5 product ending checks. Various product course of choices are as but untested: additional testwork is budgeted and is at present within the starting stage.

Elemental extraction outcomes achieved up to now embody:

Acid bake water leach checks on rougher flotation focus have achieved 98% TiO2 extraction to the liquor part.Titanium hydrolysis and calcination has been efficiently utilized to the leach liquor after iron conversion, producing a low-impurity TiO2 product containing 99.25% TiO2.Restoration within the hydrolysis stage requires additional testwork because the situations utilized within the checks and has not but been optimised. Hydrolysis is a typical course of utilized in sulphate pigment {industry}, and excessive recoveries (higher than 95%) are achieved on a business scale.

Determine 4. Elemental Extraction testwork (L-R): Acid-Focus mixing pre-acid bake, Acid bake product, preliminary phases of water leach, water leach residue and filtrate.

Product Potential

A quick-tracked separate work programme was undertaken to find out whether or not an impurity-free excessive grade product could possibly be created from samples taken at Pitfield. The pattern was processed by scrubbing, gravity separation, flotation, acid bake/water leach, impurity removing, titanium hydrolysis and calcination. The flowsheet used and situations chosen have been based mostly on industrial examples and literature. This work achieved a product grade of 99.25% TiO2: impurity ranges, significantly colorformers which impression negatively on pigment high quality, have been beneath detection limits or very low. (Announcement “Distinctive Excessive-Purity TiO2 Product Achievement” 9 June 2025).

Additional work is ongoing to grasp the TiO2 pigment market, optimise the check situations and likewise perceive the choice product choices, akin to TiCl4 (the feedstock for making titanium sponge steel) or different titanium chemical compounds.

Figure5. Purification and Product ending testwork (L-R): titanyl sulphate resolution from leaching stage, hydrated TiO2 produced from hydrolysis, and the calcined TiO 2 product

Future metallurgical testwork

Empire has dedicated important assets to allow the method flowsheet improvement programme to proceed to proceed at tempo. This contains not solely the allocation of a number of full time Empire technical workers but in addition the usage of numerous {industry} specialists who assist the Empire group in managing the required metallurgical testwork and analysis programmes.

Over the approaching months the Firm will concentrate on optimising the mineral separation phases to additional enhance the flotation and gravity focus grades and restoration. Bulk metallurgical testwork has commenced, utilising giant scale scrubbing, gravity and flotation check gear at native mineral processing laboratories. This testwork will produce important portions of titanium mineral concentrates: permitting the testing of a number of downstream beneficiation choices aimed toward defining the optimum hydrometallurgical processing route.

Completed product optimisation, by analysis and laboratory testwork, is constant and is aimed toward additional refining the +99% titanium product already achieved up to now, various titanium merchandise for advertising functions.

The following steps for the mineral separation flowsheet improvement will probably be additional optimisation of the chemistry and situations, bigger scale batch testwork after which steady piloting may be undertaken at a laboratory scale. Testwork up to now has proven the Pitfield weathered ores amenability to traditional mineral separation, beneficiation and refining strategies, and this avoids the necessity to construct a bespoke, demonstration plant. An easier and decrease value steady pilot plant operation may be established, utilising native, internationally accredited business metallurgical laboratories.

The Firm goals to finish the bench and enormous scale batch metallurgical testwork part by Q1 2026, which is when it expects to maneuver towards steady piloting of the method to be able to present the crucial technical data for the event of a business course of flowsheet and to allow the availability of bulk product samples to potential finish customers.

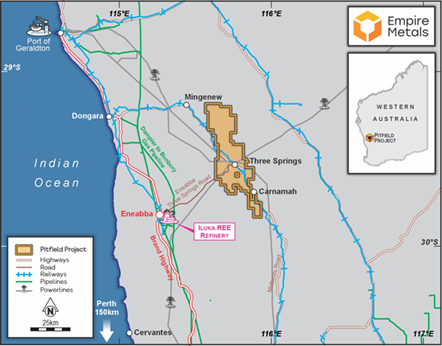

The Pitfield Titanium Challenge

Positioned inside the Mid-West area of Western Australia, close to the northern wheatbelt city of Three Springs, the Pitfield titanium undertaking lies 313km north of Perth and 156km southeast of Geraldton, the Mid West area’s capital and main port. Western Australia is a Tier 1 mining jurisdiction, with mining-friendly insurance policies, secure authorities, transparency, and superior know-how experience. Pitfield has current connections to port (each street & rail), HV energy substations, and is close by to pure fuel pipelines in addition to a inexperienced power hydrogen gasoline hub, which is underneath planning and improvement (refer Determine 3).

Determine 3. Pitfield Challenge Location exhibiting theMid-West Area Infrastructure and Companies

Competent Particular person Assertion

The scientific and technical data on this report that pertains to course of metallurgy relies on data reviewed by Ms Narelle Marriott, an worker of Empire Metals Australia Pty Ltd, an entirely owned subsidiary of Empire. Ms Marriott is a member of the AusIMM and has enough expertise related to the model of mineralisation and kind of deposit into consideration and to the exercise being undertaken to qualify as a Competent Particular person as outlined within the JORC Code 2012. Ms. Marriott consents to the inclusion on this announcement of the issues based mostly on their data within the type and context through which it seems.

The technical data on this report that pertains to the Pitfield Challenge has been compiled by Mr Andrew Faragher, an worker of Empire Metals Australia Pty Ltd, an entirely owned subsidiary of Empire. Mr Faragher is a Member of the Australian Institute of Mining and Metallurgy. Mr Faragher has enough expertise that’s related to the model of mineralisation and kind of deposit into consideration and to the exercise being undertaken to qualify as a Competent Particular person as outlined within the 2012 Version of the ‘Australasian Code for Reporting of Exploration Outcomes, Mineral Assets and Ore Reserves’. Mr Faragher consents to the inclusion on this launch of the issues based mostly on his data within the type and context through which it seems.

Market Abuse Regulation (MAR) Disclosure

Sure data contained on this announcement would have been deemed inside data for the needs of Article 7 of Regulation (EU) No 596/2014, as included into UK legislation by the European Union (Withdrawal) Act 2018, till the discharge of this announcement.

**ENDS**

For additional data please go to www.empiremetals.co.uk or contact:

Empire Metals Ltd

Shaun Bunn / Greg Kuenzel / Arabella Burwell

Tel: 020 4583 1440

S. P. Angel Company Finance LLP (Nomad & Dealer)

Ewan Leggat / Adam Cowl

Tel: 020 3470 0470

Shard Capital Companions LLP (Joint Dealer)

Damon Heath / Erik Woolgar

Tel: 020 7186 9950

St Brides Companions Ltd (Monetary PR)

Susie Geliher / Charlotte Web page

Tel: 020 7236 1177

About Empire Metals Restricted

Empire Metals is an AIM-listed and OTCQB-traded exploration and useful resource improvement firm (LON: EEE) with a main concentrate on creating Pitfield, an rising large titanium undertaking in Western Australia.

The high-grade titanium discovery at Pitfield is of unprecedented scale, with airborne surveys figuring out a large, coincident gravity and magnetics anomaly extending over 40km by 8km by 5km deep. Drill outcomes have indicated glorious continuity in grades and consistency of the mineralised beds and make sure that the sandstone beds maintain the higher-grade titanium dioxide (TiO₂) values inside the interbedded succession of sandstones, siltstones and conglomerates. The Firm is targeted on two key prospects (Cosgrove and Thomas), which have been recognized as having thick, high-grade, near-surface, bedded TiO₂ mineralisation, every being over 7km in strike size.

An Exploration Goal* for Pitfield was declared in 2024, overlaying the Thomas and Cosgrove mineral prospects, and was estimated to comprise between 26.4 to 32.2 billion tonnes with a grade vary of 4.5 to five.5% TiO2. Included inside the whole Exploration Goal* is a subset that covers the weathered sandstone zone, which extends from floor to a median vertical depth of 30m to 40m and is estimated to comprise between 4.0 to 4.9 billion tonnes with a grade vary of 4.8 to five.9% TiO2.

The Exploration Goal* covers an space lower than 20% of the general mineral system at Pitfield which demonstrates the potential for important additional upside.

Empire is now accelerating the financial improvement of Pitfield, with a imaginative and prescient to supply a high-value titanium steel or pigment high quality product at Pitfield, to grasp the total worth potential of this distinctive deposit.

The Firm additionally has two additional exploration initiatives in Australia; the Eclipse Challenge and the Walton Challenge in Western Australia, along with three valuable metals initiatives positioned in a traditionally high-grade gold producing area of Austria.

*The potential amount and grade of the Exploration Goal is conceptual in nature. There was inadequate exploration to estimate a Mineral Useful resource and it’s unsure if additional exploration will outcome within the estimation of a Mineral Useful resource.

This data is supplied by RNS, the information service of the London Inventory Alternate. RNS is accepted by the Monetary Conduct Authority to behave as a Main Data Supplier in the UK. Phrases and situations regarding the use and distribution of this data could apply. For additional data, please contact rns@lseg.com or go to www.rns.com.

Supply

Click on right here to attach with Empire Metals (OTCQB:EPMLF, AIM:EEE) to obtain an Investor Presentation